DS402 State Machine

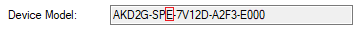

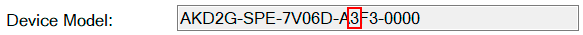

The device control of the AKD2G can be used to carry out all the motion functions in the corresponding modes. The control of the AKD2G is implemented through a mode-dependent state machine. The mode of operation is set through object 6060h, 6860h Modes of operation - AxisX. There are separate state machines for each axis.

- Object 6060h, 6860h Modes of operation - AxisX controls the state machine.

- Object 6061h, 6861h Modes of operation display - AxisX indicates the states of the state machine.

-

- The fieldbus state machine controls the axis as long as AXIS#.CMDSOURCE is equal to “Fieldbus”. To enable the axis using WorkBench and bypass the DS402 state machine, a command source other than “fieldbus” should be selected for AXIS#.CMDSOURCE. During commissioning and performing initial procedures like tuning, it is recommended the fieldbus master is OFF (not running) or not connected and the command source is “Service”.

State Machine (DS402)

State Machine Description

| State | Description |

|---|---|

| Not Ready for Switch On | Axis is not ready to switch on, initialization has not completed. |

| Switch On Disable | Axis is ready to switch on, parameters can be transferred, the bus voltage can be switched on, motion functions cannot be carried out yet. |

| Ready to Switch On | Bus voltage may be switched on, parameters can be transferred, motion functions cannot be carried out yet. |

| Switched On | Bus voltage must be switched on, parameters can be transferred, motion functions cannot be carried out yet. |

| Operation Enable | No fault present, output stage and motion functions are enabled. |

| Quick Stop Active | Drive has been stopped with the emergency ramp, output stage is enabled, motion functions are not enabled. |

| Fault Reaction Active | A fault has occurred, the drive is in process of stopping with the quick stop ramp. |

| Fault | A fault is active, the drive has been stopped and disabled. |

Transitions of the state machine

The state transitions are affected by internal events (ex: switching off the bus voltage, WorkBench enable/disable) and by the flags in the controlword (bits 0,1,2,3,7).

| Transition | Event | Action |

|---|---|---|

| 0 | Reset | Initialization |

| 1 | Initialization completed successfully. The axis is ready to operate. | None |

| 2 | Bit 1 Disable Voltage and Bit 2 Quick Stop are set in the controlword (Shutdown command). Bus voltage may be present. | None |

| 3 | Bit 0 is also set (Switch On) and bus voltage is present | None |

| 4 | Bit 3 is also set (Enable Operation) | Torque is applied to axis and motion function is enabled, depending on the mode that is set. |

| 5 | Bit 3 is canceled (Disable Operation) | Output stage is disabled. No torque applied to motor. |

| 6 | Bit 0 is canceled (Shutdown) | None |

| 7 | Bits 1 and 2 are canceled (Quick Stop/Disable Voltage) | None |

| 8 | Bit 0 is canceled (Shutdown) | Output stage is disabled. No torque applied to motor. |

| 9 | Bit 1 is canceled (Disable Voltage) | Output stage is disabled. No torque applied to motor. |

| 10 | Bits 1 and 2 are canceled (Quick Stop/Disable Voltage) | Output stage is disabled. No torque applied to motor. |

| 11 | Bit 2 is canceled (Quick Stop) | Drive is stopped with the emergency braking ramp. The output stage remains enabled. Setpoints are canceled (motion block number, digital setpoint, speed for jogging or homing). Bit 2 must be set again to perform any further motion. |

| 12 | Bit 1 is canceled (Disable Voltage) | Output stage is disabled. No torque applied to motor. |

| 13 | Fault reaction active | Execute appropriate fault reaction |

| 14 | Fault reaction is completed | Drive function is disabled. The power section may be switched off. |

| 15 | "Fault Reset" command received from host | A reset of the fault condition is carried out if no fault exists currently on the drive. After leaving the state Fault the Bit7 'Reset Fault' of the controlword must be cleared by the host. |

| 16 | Bit 2 is set | Motion function is reenabled as long as the quick stop action has completed and standstill has been reached. |

Controlword Object 6040h

The control commands are built from the logical combination of the bits in the controlword and external signals (example: enable output stage).

Bit assignment in controlword

| Bit | Name |

|---|---|

|

0 |

Switch on |

|

1 |

Disable voltage |

|

2 |

Quick stop |

|

3 |

Enable operation |

|

4 |

Operation mode specific |

|

5 |

Operation mode specific |

|

6 |

Operation mode specific |

|

7 |

Reset fault (only effective for faults) |

|

8 |

Pause/halt |

|

9 |

Operation mode specific |

|

10 |

Reserved |

| 11 | AXIS#.CANOPEN.CONTROLBIT11.MODE |

| 12 | AXIS#.CANOPEN.CONTROLBIT12.MODE |

| 13 | AXIS#.CANOPEN.CONTROLBIT13.MODE |

| 14 | AXIS#.CANOPEN.CONTROLBIT14.MODE |

| 15 | AXIS#.CANOPEN.CONTROLBIT15.MODE |

Controlword bits 11-15 mode

Controlword bits 11-15 are defined to be manufacturer specific by the DS402 standard. For AKD2G, specific modes can be set for each bit that defines the behavior. See AXIS#.CANOPEN.CONTROLBIT##.MODE for available mode descriptions.

Commands in the controlword

| Command | Bit 7 Fault Reset | Bit 3 Enable Operation | Bit 2 Quick stop | Bit 1 Disable Voltage | Bit 0 Switch On | Transitions |

|---|---|---|---|---|---|---|

|

Shutdown |

X |

X |

1 |

1 |

0 |

2, 6, 8 |

|

Switch on |

X |

X |

1 |

1 |

1 |

3 |

|

Disable voltage |

X |

X |

X |

0 |

X |

7, 9, 10, 12 |

|

Quick stop |

X |

X |

0 |

1 |

X |

7, 10, 11 |

|

Disable operation |

X |

0 |

1 |

1 |

1 |

5 |

|

Enable operation |

X |

1 |

1 |

1 |

1 |

4 |

|

Fault reset |

1 |

X |

X |

X |

X |

15 |

Bits marked by an X are irrelevant.

Mode-dependent bits in the controlword

The following table shows the mode-dependent bits in the controlword. Only manufacturer-specific modes are supported at present. The individual modes are set by object 6060h, 6860h Modes of operation - AxisX.

| Operation Mode | No. | Bit 4 | Bit 5 | Bit 6 | Bit 9 |

|---|---|---|---|---|---|

| Analog velocity | FEh | reserved | reserved | reserved | reserved |

| Analog torque | FFh | reserved | reserved | reserved | reserved |

| Profile position mode (pp) | 01h | New set-point | Use new set-point immediately |

0 - Absolute move 1 - Relative move |

Blend / only the fly move once target position is reached |

| Profile velocity mode (pv) | 03h | reserved | reserved | reserved | reserved |

| Profile torque mode (tq) | 04h | reserved | reserved | reserved | reserved |

| Homing mode (hm) | 06h | Start homing operation | reserved | reserved | reserved |

| Cyclic sync position Mode (csp) | 08h | reserved | reserved | reserved | reserved |

| Cyclic sync velocity mode (csv) | 09h | reserved | reserved | reserved | reserved |

Description of the remaining bits in the controlword

The remaining bits in the controlword that are not used for drive state machine commands or operation mode specific commands are used for special operations:

Bit 8 – Pause/Halt: If bit 8 is set, then the drive halts (pauses) in all modes. The set-points (speed for homing or jogging, motion task number, setpoints for digital mode) for the individual modes are retained.

Statusword 6041h

The momentary state of the state machine can be read with the aid of the statusword.

| Index | Sub-Index | Data Type | Access | PDO Mappable | Description |

|---|---|---|---|---|---|

| 0x6041 | 0 | Unsigned16 | RW | TxPDO | Drive state machine statusword |

Bit assignment in the statusword

| Bit | Name | Description |

|---|---|---|

| 0 |

Ready to switch on |

Controlled by state machine |

| 1 |

Switched on |

Controlled by state machine |

| 2 |

Operation enabled |

Controlled by state machine |

| 3 |

Fault |

Axis fault is active |

| 4 |

Voltage enabled |

Bus voltage is present |

| 5 |

Quick stop |

Controlled by state machine |

| 6 |

Switch on disabled |

Controlled by state machine |

| 7 |

Warning |

Axis warning active |

| 8 | STO – Safe Torque Off | STO is preventing drive from enabling (AXIS#.SAFE.STO.ACTIVE) |

| 9 | Remote |

1 – Fieldbus in control (AXIS#.CMDSOURCE = Fieldbus) 0 – WorkBench in control (AXIS#.CMDSOURCE = Service) |

| 10 | Target reached |

Axis has reached target value. In Profile Position Mode and Homing Mode the position window is set using AXIS#.SETTLE.P. The behavior can be configured by AXIS#.CANOPEN.TARPOSMODE. In Profile velocity and Analog velocity modes, this bit is set when AXIS#.VL.FB is within the window set using the object 606Dh, 686Dh Velocity window - AxisX sub 0 and a window time is set using object 606Eh, 686Eh Velocity window time - AxisX sub 0. The bit is also set on coming to standstill on Halt bit (bit 8 of Controlword = 1) or after Quickstop (bit 2 of Controlword = 0) with quick stop option code 5 or 6. |

| 11 | Internal limit active |

This bit is controlled by the conditions below:

|

| 12 | Operation mode specific (reserved) | See Mode-dependent bits in the statusword |

| 13 | Operation mode specific (reserved) | See Mode-dependent bits in the statusword |

| 14 | Ramp Down Requested | SIL3 drives only. Indicates that a SS1 input was triggered and the master should stop the axis. STO will be triggered in configured SS1_t amount of time for instance of SS1 that was triggered. |

| 15 | Manufacturer-specific (reserved) |

States of the state machine

Bits marked by X are irrelevant

| State | Bit 6 switch on disabled | Bit 5 quick stop | Bit 3 fault | Bit 2 operation enabled | Bit 1 switched on | Bit 0 ready to switch on |

|---|---|---|---|---|---|---|

|

Not ready to switch on |

0 |

X |

0 |

0 |

0 |

0 |

|

Switch on disabled |

1 |

X |

0 |

0 |

0 |

0 |

|

Ready to switch on |

0 |

1 |

0 |

0 |

0 |

1 |

|

Switched on |

0 |

1 |

0 |

0 |

1 |

1 |

|

Operation enabled |

0 |

1 |

0 |

1 |

1 |

1 |

|

Fault |

0 |

X |

1 |

0 |

0 |

0 |

|

Fault reaction active |

0 |

X |

1 |

1 |

1 |

1 |

|

Quick stop active |

0 |

0 |

0 |

1 |

1 |

1 |

Mode-dependent bits in the statusword

The following table shows the mode-dependent bits in the statusword. The individual modes are set by object 6060h, 6860h Modes of operation - AxisX.

| Modes of Operation | No. | Bit 12 | Bit 13 |

|---|---|---|---|

| Analog velocity | FEh | This bit is 1 while the motor is at standstill (see AXIS#.ZEROREACHED). | Not used |

| Analog torque | FFh | This bit is 1 while the motor is at standstill (see AXIS#.ZEROREACHED). | Not used |

| Profile position mode (pp) | 01h | Set-point acknowledge | Following error |

| Profile velocity (pv) | 03h | This bit is 1 while the motor is at standstill (see AXIS#.ZEROREACHED). | Not used |

| Homing mode (hm) | 06h | Homing attained | Homing error |

| Cyclic sync position mode (csp) | 08h | This bit stays on 1 as long as the drive is following the position set-points. | Following error |

| Cyclic sync velocity mode (csv) | 09h | This bit stays 1 as long as the drive is following velocity set-points | Not used |